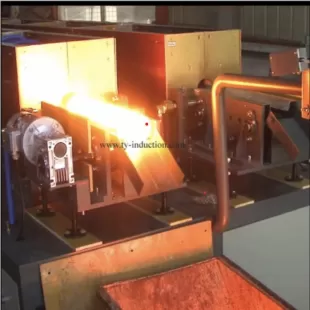

Questions to Ask Before Ordering Induction Forging Machine

Investing in an induction forging machine is a critical decision that can significantly impact your production efficiency, product quality, and operational costs. Whether you're upgrading your current equipment or entering the forging industry for the first time, asking the right questions will help ensure that you select a machine tailored to your specific needs.

What Are Your Production Requirements?

Before contacting suppliers, define your production volume, material types, and forging frequencies. These variables determine the power capacity, heating speed, and coil design necessary for your operation.

Material Type: Different metals—steel, aluminum, brass, titanium—have unique heating characteristics. Ensure the machine can accommodate your specific alloys.

Part Dimensions: Larger or irregularly shaped workpieces need custom coils and higher power settings.

Throughput Goals: Are you forging small batches or continuous production? Clarify your needs to match machine duty cycles.

Is the Machine Compatible with Your Existing Infrastructure?

Check whether the electrical requirements, cooling systems, and floor space are compatible with your facility.

Power Supply: Does the machine require 480V or 380V? Is your facility equipped to handle the load?

Water Cooling System: Induction machines require reliable cooling. Ask if the cooling system is included or must be installed separately.

Space & Layout: Assess the available space in your workshop. Verify if the machine fits and if there’s room for safe operation and maintenance.

What Is the Machine's Power and Frequency Range?

Induction forging relies on precise control of power (kW) and frequency (kHz) for optimal results. Selecting the right parameters is key.

High Frequency (100–400 kHz): Ideal for small parts and shallow heating.

Medium Frequency (3–100 kHz): Suitable for larger cross-sections and deeper heat penetration.

Power Output: Choose a machine that delivers sufficient energy without overloading.

Is the Machine Designed for Your Specific Application?

Every application has unique heating profiles. Choose a machine that supports:

Bar End Heating

Billet Heating

Die Heating

Preheating for Bending or Forming

Ensure the supplier has experience in your industry segment and can provide proven solutions tailored to your product geometry and production rate.

What Is the Coil Design and Customization Capability?

Induction coils are the heart of the machine. Ask if custom coil design is available, especially if you deal with unique part geometries.

Single-Turn vs Multi-Turn Coils

Split Coils for Easier Loading

Changeable Coil Heads for Different Applications

Additionally, inquire about coil lifespan, ease of replacement, and spare parts availability.

Does It Include a PLC or HMI Control System?

Modern machines should feature programmable logic controllers (PLC) or human-machine interfaces (HMI) for better operation.

Programmable Heating Profiles

Temperature Monitoring and Control

Data Logging and Fault Diagnosis

Remote Access and Troubleshooting

These systems improve consistency, reduce manual intervention, and allow integration with automation lines.

What Safety Features Are Included?

Safety is non-negotiable in high-heat forging environments. Ask about:

Emergency Stop Functions

Overheat Protection

Electrical Insulation

Safety Interlocks

Enclosed Coils and Shielding

Ensure the machine complies with international safety standards, such as CE or UL certification.

What Are the Maintenance Requirements and Lifecycle Costs?

Total cost of ownership goes beyond purchase price. Ask about:

Routine Maintenance Schedules

Component Lifespan

Service Intervals

Spare Parts Availability

Ease of Access to Components

Preventive maintenance can significantly extend the life of your machine and reduce downtime.

Is On-Site Training and Support Provided?

Even the most advanced machine is only as good as its operator. Check if the vendor provides:

Initial On-Site Setup and Commissioning

Operator Training

Maintenance Instruction

Technical Documentation and User Manuals

Some suppliers also offer remote monitoring, online training modules, and scheduled check-ups.

What Is the Lead Time and Warranty Policy?

Delays in delivery can disrupt your production timeline. Ask clearly about:

Manufacturing Lead Time

Shipping Duration

Installation Timeline

Standard Warranty Terms (1–2 years)

Extended Service Contracts

Also, confirm how quickly service technicians can respond in case of a breakdown.

Does the Supplier Offer After-Sales Service and Spare Parts?

A good supplier relationship doesn’t end at purchase. Reliable after-sales support ensures uninterrupted operations.

Local Service Availability

Remote Diagnostic Tools

24/7 Technical Helpline

Stocked Inventory for Critical Parts

Confirm whether the supplier offers annual service contracts or priority maintenance packages.

What Are the Energy Efficiency Features?

Energy usage directly impacts your operational costs. Ask about:

Energy Recovery Systems

Standby Modes

Automatic Power Regulation

Real-Time Monitoring of Power Consumption

Choosing an energy-efficient machine not only saves costs but also supports sustainability initiatives.

Can the System Be Integrated into Automation or ERP Systems?

Modern forging shops aim for Industry 4.0 integration. Ask if the machine can be connected to:

Robotic Loading Systems

SCADA Systems

ERP Software

Cloud-Based Monitoring

Integration streamlines production, improves quality tracking, and facilitates data-driven decisions.

Is There a Reference List of Existing Clients?

Reputation matters. A reliable supplier should provide a list of previous clients or case studies demonstrating successful installations.

Client Testimonials

Before & After Use Cases

Process Improvement Metrics

Repeat Purchases by Existing Clients

This shows that the machine performs reliably in real-world conditions.

Conclusion

Before placing your order, carefully evaluate your production requirements, infrastructure compatibility, and technical specifications. Speak with multiple suppliers, compare offerings, and request customized solutions. A well-informed decision will help you maximize ROI, reduce downtime, and maintain high product standards.